Some customers’ machines like a new machine even though it has worked for several years and some customers’ machines didn’t use for a long time, but machines like a long used machine and often have many problems. Because maintenance habits make a big difference. Now, the WILL engineer gives you some reliable ways to maintain your machine.

1. keep good hygiene, do not let dust influence your machine and print heads. The temperature was set at around 25 degrees. And humid also should keep 35–65 %Rh (No condensation), and the room should have good ventilation. It is good for both humans and machines because ink is a kind of chemistry.

2. Obey the right order to start and shut down a machine. Start machine order: turn on machine—> start the software, shut down machine order: close software —-> turn off a machine. and the quality of clean cloth for wiping print head nozzles should qualified(bad quality cloth will damage the print head nozzles). Wipe nozzles should only wipe in one direction and lightly, Do not wipe back and forth hard, fold the cloth and wipe nozzles, use a new place for wiping new color, do not mix use and cause color mixture.

3. Should have worker aside by machine when it is working(if something wrong happens, press any emergency button first, it will protect the machine and cause less damage), do not let material problem cause damage to printhead nozzles, otherwise, it will cause irrevocable damage to the print head.

4. Purge and print a status after everyday work. Then check the nozzles situation, if nozzles clog, then purge more ink until it gets better.

5. If turn off the machine, the valves of sub-ink tanks should also be closed, otherwise, the ink will flow out from nozzles and cause waste and pollution, if you have a stable electricity supply, it is better to let the machine turn on all the time, the machine is flashing all the time will keep print head nozzles at the good situation, and the next day before production, the first thing is to print status and check nozzles situation.

6. The carriage should be covered if the machine is not working because the light and dust will influence the print head nozzles.

7. The filters for ink should be changed every 3 months, otherwise, the filter will clog after a long time of use.

8. The X and Y motion parts(guide railway, slider, and lead screw) of the machine should add lubricating oil regularly. Especially x motion is a high-speed move.

9. Turn off the water chiller when the machine is free at night, This will save more power and save the UV lamp’s lifetime.WILL engineer will give more advice when installing the machine for you, And feel the best services from us.

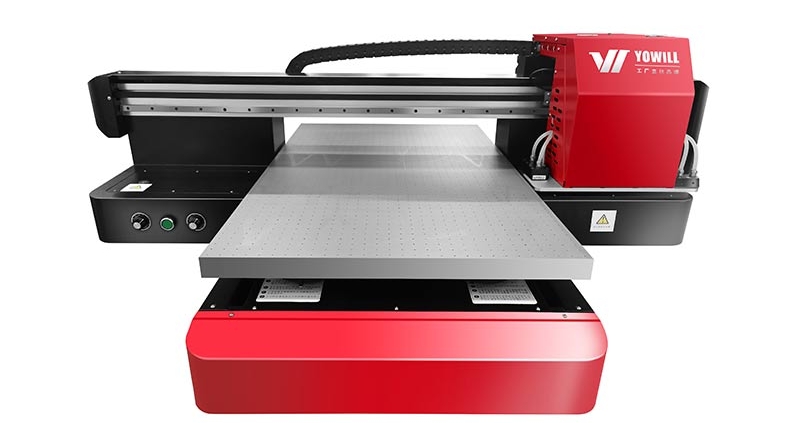

1. Green and environmental protection

The UV flatbed printer adopts computer control, and only needs to be inkjet according to the demand, which will not waste resources, no noise will be generated during the printing process, and green printing can be realized.

2. The color of the image is clear

The UV flatbed printer prints excellent results, whether it is a color pattern or a complex gradient print, the effect is perfect. This greatly improves the quality of the product. The print effect is artistic and the stereo effect is strong. Whether it’s individual printing or batch printing, it’s perfect for the desired effect.

3. Print embossed and other stereo effects

The UV flatbed printer can not only print flat patterns but also make relief effects on the surface of the object. This makes the print effect more stereoscopic, which is not possible with ordinary printers.

4. Fast printing speed

In the past, the printing process took several days from design to proof of molding, but using UV printing technology only took a few minutes to see the print. Customers only need to choose to print samples, they can wait for effect, which really improves the work efficiency.

First, a good working conditions:

1.Temperature as well as Humidity Maintain the temperature between 18-28 degrees particularly in winter. The humidity is usually around 30-50 RH.

2.Ray of ultraviolet light: UV ink can cure when exposed to light, so it is important to ensure that there isn’t bright light inside the area.

3.Wind. Many workshops have fans in the summer. The fans boost air flow, then the head becomes easy to dry and then blockage.

4.Clean. If the work area is full of dust, the particles could stick to the nozzles and cause clogging.

Secondly, proper operation:

1.Please take note of the height of the materials prior to printing. Many customers fail to adjust the height after changing the material, and then the printer head is damaged directly because of the cash in the carriage.

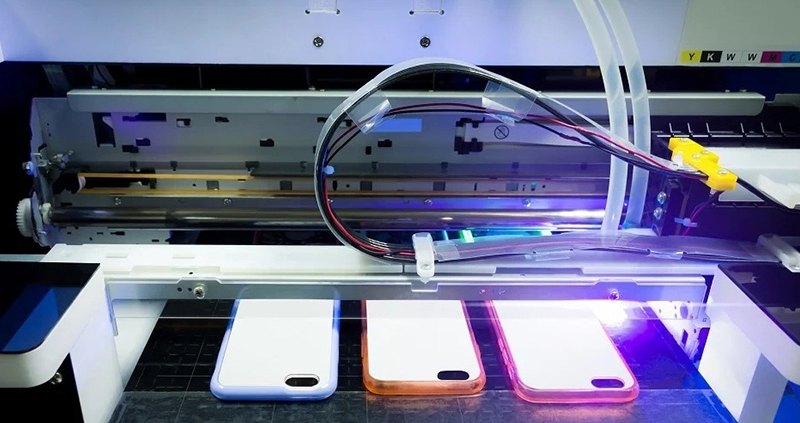

2.Nozzle test every day prior to printing. If there are one or more nozzles not present, clean the software right away. If you find that the head is blocked severely then clean it gentle and gently using a syringe. ( Why do you need to clean gently and softly? The higher pressure could damage the head and cause mixing of ink.) Be sure to not immerse the entire printer head in the cleaning solution!

3.Keep the printer head cable in good condition. If the cable becomes dirty(especially the port made of metal) the head can be burnt.

Tips: Most damaged heads do not last for a long time however, they are damaged due to uncleaning. A proper method of sucking ink will prolong the life of the printer head. To clean the printer head, email us for the video tutorial.

Thirdly, ensure that head nozzles are moisturized .

1.If the printer has capping You just need to ensure that the nozzle stays connected properly to the capping. The YOWILL UV printer has a lifting capping stations that can be sealed to stop dust and air-dry. It is also possible to put moisturizing or cleaning liquid on the capping for a longer period(such as 3-7 days) absence of use.

2.If printers do not come with capping services You can apply cleaning liquid on non-woven fabric and then put the carriage there. Keep checking and filling cleaning liquid every two days to ensure that the nozzle is not dry.

The advertising industry benefits from the development of urban transport, commercial building, and data technology has become an indispensable industry, outdoor advertising with high arrival rate, strong visual impact, long distribution time, thousands of low-cost, high urban coverage, a single media dispersed but a large number of advantages has become a brand campaign of public communication channels, the following TV, the third largest media after the network. With the screen printing, net printing, watermark, inkjet, photo equipment development, UV Flatbed printers have been widely used in the advertising industry.

Recently, the Internet advertising market share will become larger and bigger, the network becomes the main position of advertising main marketing. Under the impact of the continuous development of the Internet, outdoor advertising is facing great pressure. Outdoor companies are bound to scale, specialization in the field of development, with quality services and leading technology to improve competitive advantage!

The advantages of UV Flatbed printers in the advertising industry:

1. UV Flatbed printers operation is simple, save manpower, print out the product waterproof sunscreen anti-ultraviolet, more environmentally friendly.

2. UV Flatbed printers can be personalized design, personalized printing, so that each unique creativity is vividly displayed in front of others, understand the true meaning of advertising and creativity, to do with other people, then, you sell is not advertising, not products, but your creativity.

3. UV Flatbed printers can be printed on a variety of media above, glass, acrylic, PVC, metal, etc., can be used for a more than one machine, mechanized production scale can greatly improve production efficiency.

We believe that outdoor advertising will continue to be stable with the development of the economy, and still have a bright future.

More industry information, Welcome to consult YOWILL Technology.